Pioneering Biofabrication: The Fusion of Hydrogels and Fibers by Bayreuth Researchers

At the University of Bayreuth, a ground-breaking development in medical technology is underway. Dr. Leonid Ionov and his colleagues are expanding the possibilities of biofabrication by using a cutting-edge 3D bioprinting technique. With the use of this novel technique, hydrogels and fibers can be combined to create tissue constructs that closely resemble the intricate architecture of human organs. This discovery not only signals a new era in tissue engineering but also provides hope for resolving the world’s organ shortage.

The Innovation at Bayreuth

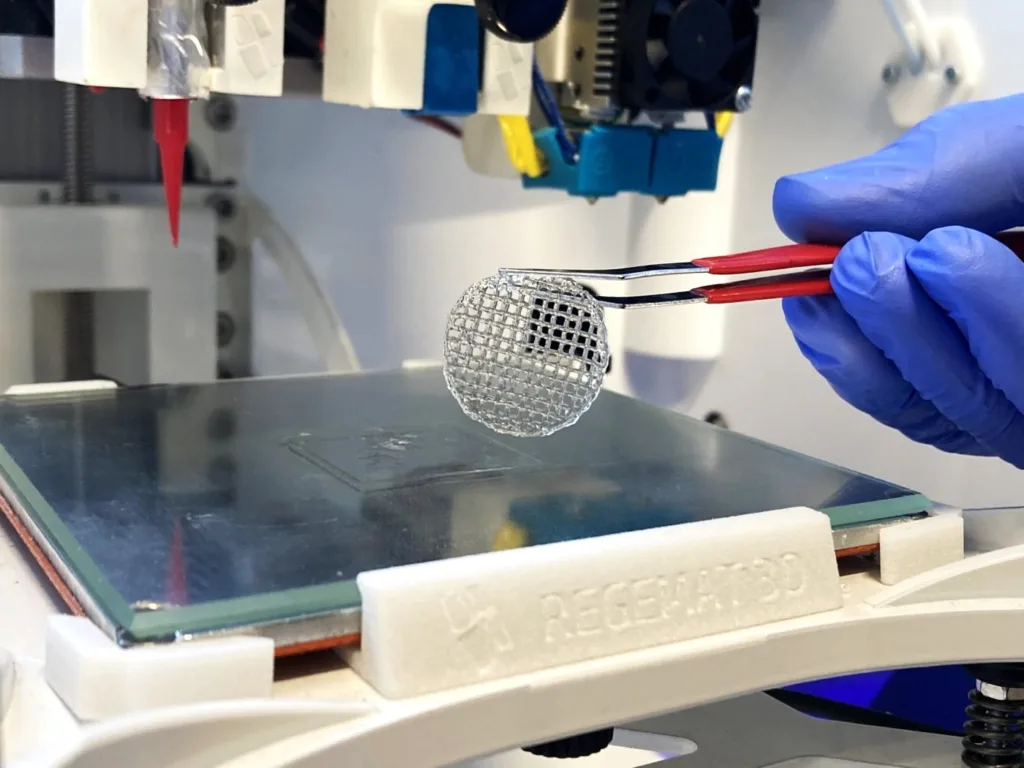

The University of Bayreuth’s latest contribution to the field of biofabrication is a unique device that integrates hydrogel technology with fiber spinning, a method known as touch-spinning. This blend of technologies facilitates the creation of tissue-like structures with fibrous textures and uniaxial cell alignment, a feat that was previously unachievable in a single device. The device, which has been both invented and patented in Bayreuth, promises to significantly enhance the efficiency and effectiveness of living tissue production.

The Role of Hydrogels and Fibers

Hydrogels have long been recognized for their utility in tissue engineering, serving as scaffolding materials that support the growth and development of biological tissues. The Bayreuth team’s experiments have involved various hydrogels, assessing their properties to optimize the biofabrication process. By integrating these hydrogels with a fiber system, the researchers have managed to reduce the complexity of processing hydrogels, such as the need for cross-linking to bolster their mechanical properties. This synergy not only improves the material’s mechanical characteristics but also facilitates subsequent tissue formation.

Biofabrication with Bioprinting

Bioprinting stands out as a pivotal technique in biofabrication, offering the ability to tailor the material, physical, chemical, and biological properties of the so-called cell ink used in biomedical applications. The University of Bayreuth’s approach involves a two-step crosslinking method for preparing 3D-bioprinted hydrogel scaffolds. This process includes the physical crosslinking of alginate components with CaCl2, followed by the chemical crosslinking of GelMA components under ultraviolet light. Such advancements in bioink technology are critical for the accurate and gentle deposition of cell units, minimizing process-induced cell damage.

Looking Ahead

The strides made by Dr. Ionov and his team in combining hydrogels and fibers through 3D bioprinting technology represent a significant leap forward in the field of biofabrication. This novel approach not only simplifies the production of tissue constructs but also enhances their quality and functionality, bringing us closer to the goal of artificially producing biological tissues and organs. As this technology continues to evolve, it holds the potential to revolutionize medical treatments and organ transplantation, offering new hope to patients worldwide.

In conclusion, the University of Bayreuth’s pioneering work in biofabrication underscores the importance of interdisciplinary collaboration in advancing medical technology. By bridging the gap between hydrogels and fibers, the team has set a new benchmark in the production of lifelike tissues, opening up new avenues for research and application in tissue engineering and regenerative medicine.

References:

Sun W; Schaffer S; Dai K; Yao L; Feinberg A; Webster-Wood V 3D Printing Hydrogel-Based Soft and Biohybrid Actuators: A Mini-Review on Fabrication Techniques, Applications, and Challenges. Frontiers in Robotics and AI 2021, 8, 1–10. [PMC free article] [PubMed] [Google Scholar]

Raviv D; Zhao W; McKnelly C; Papadopoulou A; Kadambi A; Shi B; Hirsch S; Dikovsky D; Zyracki M; Olguin C; Raskar R; Tibbits S Active printed materials for complex self-evolving deformations. Sci. Rep 2014, 4, 1–9. [PMC free article] [PubMed] [Google Scholar]

Xiong Z; Zheng ML; Dong XZ; Chen WQ; Jin F; Zhao ZS; Duan XM Asymmetric microstructure of hydrogel: Two-photon microfabrication and stimuli-responsive behavior. Soft Matter 2011, 7, 10353–10359. [Google Scholar]

Xing JF; Zheng ML; Duan XM Two-photon polymerization microfabrication of hydrogels: an advanced 3D printing technology for tissue engineering and drug delivery. Chem. Soc. Rev 2015, 44, 5031–5039. [PubMed] [Google Scholar]

Ovsianikov A; Gruene M; Pflaum M; Koch L; Maiorana F; Wilhelmi M; Haverich A; Chichkov B Laser printing of cells into 3D scaffolds. Biofabrication 2010, 2, 014104. [PubMed] [Google Scholar]

I like this! Is there anything more I should think about next? Or is this okay?

We’re glad to hear you’re on board with our approach! Moving forward, it might be beneficial to keep an eye out for any emerging trends or feedback from your audience that could inform future content or initiatives. Staying adaptable and open to new ideas is key.

If you’re looking for specific areas to explore next, consider diving deeper into topics that resonate with your audience or experimenting with new formats that could enrich their experience. Your engagement and willingness to innovate are what make this journey exciting.

Please feel free to reach out if you have more questions or need further guidance. We’re here to support you.

Please assist us in spreading the word about our website.

Best wishes,

Find Soft News Research Team

Really enjoyed this article, can you make it so I get an update sent in an email whenever you publish a fresh post?

The core of your writing whilst sounding agreeable originally, did not really sit properly with me after some time. Someplace throughout the sentences you were able to make me a believer but only for a very short while. I nevertheless have a problem with your leaps in logic and one might do well to help fill in all those gaps. In the event you actually can accomplish that, I will definitely end up being amazed.

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

I do agree with all the ideas you have presented in your post. They are very convincing and will certainly work. Still, the posts are very short for novices. Could you please extend them a little from next time? Thanks for the post.

I’ll immediately grasp your rss feed as I can’t to find your email subscription hyperlink or newsletter service. Do you have any? Please let me know in order that I may subscribe. Thanks.

I am very happy to read this. This is the kind of manual that needs to be given and not the accidental misinformation that’s at the other blogs. Appreciate your sharing this best doc.

hello there and thank you for your info – I have definitely picked up anything new from right here. I did however expertise some technical issues using this web site, since I experienced to reload the web site a lot of times previous to I could get it to load properly. I had been wondering if your web host is OK? Not that I am complaining, but sluggish loading instances times will very frequently affect your placement in google and could damage your quality score if advertising and marketing with Adwords. Anyway I’m adding this RSS to my email and can look out for a lot more of your respective interesting content. Ensure that you update this again very soon..

Would love to incessantly get updated great blog! .

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point. You obviously know what youre talking about, why throw away your intelligence on just posting videos to your site when you could be giving us something informative to read?

I would like to thnkx for the efforts you have put in writing this blog. I am hoping the same high-grade blog post from you in the upcoming as well. In fact your creative writing abilities has inspired me to get my own blog now. Really the blogging is spreading its wings quickly. Your write up is a good example of it.

F*ckin’ awesome things here. I’m very glad to see your post. Thanks a lot and i am looking forward to contact you. Will you please drop me a e-mail?

Hi there! I just wish to give an enormous thumbs up for the good data you might have here on this post. I will be coming again to your weblog for more soon.

I visited a lot of website but I conceive this one contains something special in it in it

I’ve been browsing online more than 3 hours today, yet I never found any interesting article like yours. It is pretty worth enough for me. In my opinion, if all webmasters and bloggers made good content as you did, the web will be much more useful than ever before.

Hello There. I found your blog using msn. This is a very well written article. I will be sure to bookmark it and come back to read more of your useful information. Thanks for the post. I’ll certainly comeback.

I like this site very much, Its a real nice spot to read and find info . “Acceptance of dissent is the fundamental requirement of a free society.” by Richard Royster.

Hiya, I am really glad I have found this info. Nowadays bloggers publish only about gossips and internet and this is actually irritating. A good website with exciting content, this is what I need. Thanks for keeping this web site, I’ll be visiting it. Do you do newsletters? Can not find it.

Hello. splendid job. I did not imagine this. This is a fantastic story. Thanks!

I’m not sure exactly why but this website is loading incredibly slow for me. Is anyone else having this issue or is it a problem on my end? I’ll check back later and see if the problem still exists.

I?¦ve read several good stuff here. Certainly value bookmarking for revisiting. I surprise how much effort you put to create any such magnificent informative website.

I got what you mean ,saved to bookmarks, very decent web site.

It?¦s really a nice and useful piece of info. I am satisfied that you just shared this helpful information with us. Please keep us informed like this. Thank you for sharing.

This website is really a walk-by means of for all of the info you needed about this and didn’t know who to ask. Glimpse here, and also you’ll positively uncover it.

Wonderful work! This is the type of info that should be shared around the net. Shame on the search engines for not positioning this post higher! Come on over and visit my web site . Thanks =)

As a Newbie, I am continuously browsing online for articles that can help me. Thank you

I’d constantly want to be update on new content on this site, saved to favorites! .

Pretty nice post. I just stumbled upon your blog and wished to say that I have truly enjoyed surfing around your blog posts. In any case I will be subscribing to your rss feed and I hope you write again very soon!

Superb post but I was wanting to know if you could write a litte more on this subject? I’d be very thankful if you could elaborate a little bit more. Kudos!

I will right away snatch your rss as I can not in finding your email subscription link or newsletter service. Do you’ve any? Please let me realize so that I may subscribe. Thanks.

I’m really enjoying the design and layout of your blog. It’s a very easy on the eyes which makes it much more enjoyable for me to come here and visit more often. Did you hire out a designer to create your theme? Excellent work!

That is the best weblog for anyone who desires to search out out about this topic. You notice so much its virtually onerous to argue with you (not that I actually would want…HaHa). You positively put a brand new spin on a topic thats been written about for years. Great stuff, simply great!

You have observed very interesting details ! ps nice site.

you have an important blog right here! would you like to make some invite posts on my weblog?

Definitely, what a splendid website and illuminating posts, I surely will bookmark your website.Have an awsome day!

I like this post, enjoyed this one thank you for putting up. “The universe is not hostile, nor yet is it unfriendly. It is simply indifferent.” by John Andrew Holmes.

Very good written information. It will be valuable to anybody who employess it, as well as me. Keep doing what you are doing – for sure i will check out more posts.

Hey there! Do you use Twitter? I’d like to follow you if that would be okay. I’m absolutely enjoying your blog and look forward to new posts.

Hi! This post could not be written any better! Reading this post reminds me of my old room mate! He always kept talking about this. I will forward this article to him. Fairly certain he will have a good read. Many thanks for sharing!

I really enjoy looking at on this site, it holds excellent posts.

What i don’t realize is actually how you’re no longer really a lot more well-appreciated than you may be right now. You are very intelligent. You realize thus considerably in the case of this subject, produced me for my part believe it from numerous various angles. Its like men and women don’t seem to be interested until it is something to do with Woman gaga! Your personal stuffs nice. All the time deal with it up!

Greetings! I’ve been following your blog for a while now and finally got the courage to go ahead and give you a shout out from Austin Tx! Just wanted to say keep up the great job!

Super-Duper blog! I am loving it!! Will come back again. I am taking your feeds also.

Some truly prize blog posts on this internet site, saved to favorites.

What i don’t understood is if truth be told how you’re not actually much more well-liked than you may be right now. You are very intelligent. You realize thus considerably in the case of this subject, made me personally believe it from numerous numerous angles. Its like women and men are not interested unless it is one thing to do with Lady gaga! Your personal stuffs great. All the time deal with it up!

Thanks for any other great post. Where else could anyone get that kind of info in such an ideal way of writing? I’ve a presentation subsequent week, and I am at the search for such info.

As I web-site possessor I believe the content material here is rattling magnificent , appreciate it for your efforts. You should keep it up forever! Good Luck.

Thanks a bunch for sharing this with all of us you actually know what you are talking about! Bookmarked. Please also visit my site =). We could have a link exchange agreement between us!

I like this web blog its a master peace ! Glad I noticed this on google .

I reckon something really interesting about your blog so I bookmarked.

Hiya, I am really glad I’ve found this info. Nowadays bloggers publish just about gossips and web and this is actually annoying. A good blog with exciting content, this is what I need. Thank you for keeping this web-site, I’ll be visiting it. Do you do newsletters? Can not find it.

Hello, Neat post. There’s an issue along with your site in internet explorer, may check thisK IE nonetheless is the marketplace chief and a big part of people will omit your excellent writing because of this problem.

You are a very capable individual!

I like this blog very much, Its a very nice post to read and find info . “The love of nature is consolation against failure.” by Berthe Morisot.

It?¦s in reality a great and helpful piece of info. I am glad that you simply shared this helpful info with us. Please stay us informed like this. Thank you for sharing.

I do not even understand how I stopped up right here, but I thought this publish used to be good. I don’t realize who you might be but certainly you’re going to a famous blogger if you happen to are not already 😉 Cheers!

Thank you for the good writeup. It in reality was a amusement account it. Look complex to more introduced agreeable from you! However, how can we keep up a correspondence?

I like what you guys are up too. Such smart work and reporting! Carry on the excellent works guys I have incorporated you guys to my blogroll. I think it’ll improve the value of my web site 🙂

Nice weblog here! Also your website a lot up very fast! What web host are you the usage of? Can I am getting your affiliate hyperlink for your host? I wish my site loaded up as fast as yours lol

Thanks , I’ve just been searching for info approximately this subject for a while and yours is the greatest I’ve found out so far. However, what concerning the conclusion? Are you positive about the supply?

Your place is valueble for me. Thanks!…

I really like your writing style, fantastic info, regards for putting up :D. “Nothing sets a person so much out of the devil’s reach as humility.” by Johathan Edwards.

Very nice post. I just stumbled upon your blog and wanted to say that I’ve truly enjoyed surfing around your blog posts. In any case I’ll be subscribing to your rss feed and I hope you write again very soon!

Perfectly composed written content, appreciate it for entropy.

Hey There. I found your weblog the usage of msn. That is a very smartly written article. I will be sure to bookmark it and return to read extra of your useful information. Thank you for the post. I will certainly return.

Utterly pent content material, Really enjoyed looking through.

What i do not understood is actually how you are no longer actually a lot more smartly-preferred than you might be now. You’re very intelligent. You understand thus significantly in the case of this topic, produced me in my view imagine it from so many various angles. Its like women and men are not interested unless it’s one thing to accomplish with Woman gaga! Your personal stuffs outstanding. At all times maintain it up!

This is really interesting, You are a very skilled blogger. I’ve joined your rss feed and look forward to seeking more of your excellent post. Also, I have shared your website in my social networks!

Greetings! Very helpful advice on this article! It is the little changes that make the biggest changes. Thanks a lot for sharing!

Enjoyed studying this, very good stuff, thankyou.

Hiya! Quick question that’s entirely off topic. Do you know how to make your site mobile friendly? My blog looks weird when browsing from my iphone. I’m trying to find a template or plugin that might be able to fix this issue. If you have any recommendations, please share. Thanks!

Its wonderful as your other blog posts : D, appreciate it for posting.

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.

Heya i’m for the primary time here. I came across this board and I in finding It truly helpful & it helped me out a lot. I am hoping to offer one thing back and aid others such as you aided me.

I went over this internet site and I think you have a lot of wonderful information, saved to my bookmarks (:.

There are actually a lot of particulars like that to take into consideration. That is a nice level to bring up. I provide the thoughts above as general inspiration but clearly there are questions like the one you convey up the place a very powerful thing shall be working in sincere good faith. I don?t know if finest practices have emerged around issues like that, but I’m certain that your job is clearly identified as a good game. Both boys and girls feel the impression of just a moment’s pleasure, for the rest of their lives.

Throughout this awesome pattern of things you actually receive an A with regard to effort. Where you confused everybody was first in your facts. You know, they say, the devil is in the details… And it couldn’t be more true right here. Having said that, let me tell you just what did deliver the results. The article (parts of it) is quite convincing and this is possibly the reason why I am making an effort to opine. I do not make it a regular habit of doing that. 2nd, even though I can easily notice the leaps in logic you come up with, I am not certain of exactly how you appear to unite your ideas which help to make the actual final result. For now I will subscribe to your point however trust in the future you link the dots much better.

Hello.This article was really remarkable, especially because I was looking for thoughts on this issue last Wednesday.

It’s a pity you don’t have a donate button! I’d without a doubt donate to this excellent blog! I suppose for now i’ll settle for book-marking and adding your RSS feed to my Google account. I look forward to new updates and will share this site with my Facebook group. Chat soon!